EXPERIENCE A NEW DIMENSION OF MODELMAKING – WITH THE NEW MINImill KIT 2!

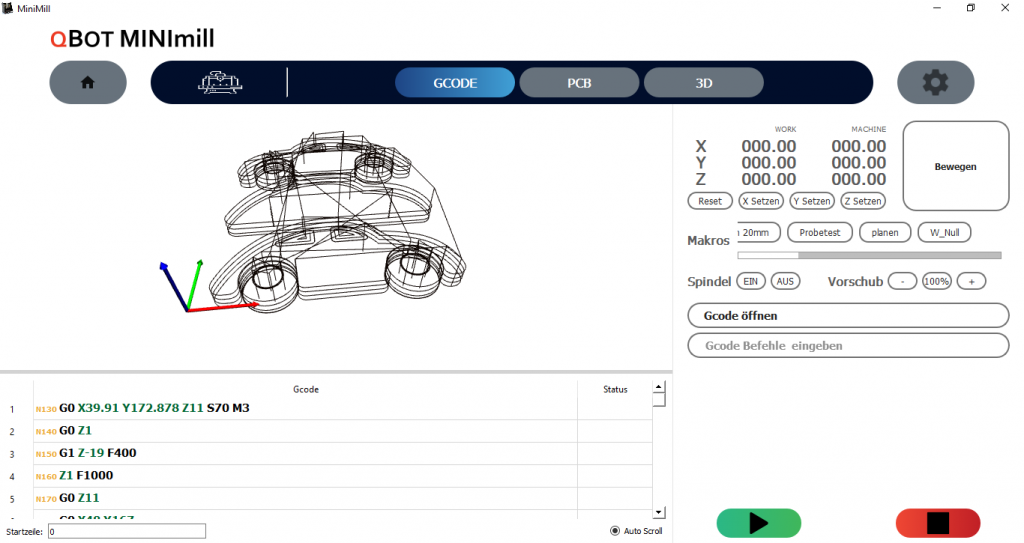

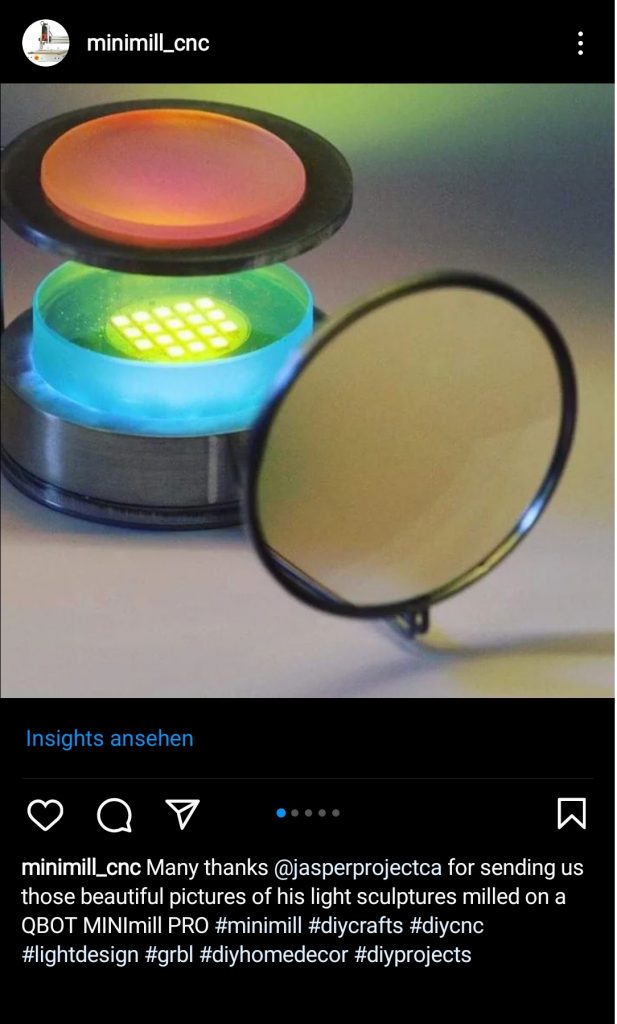

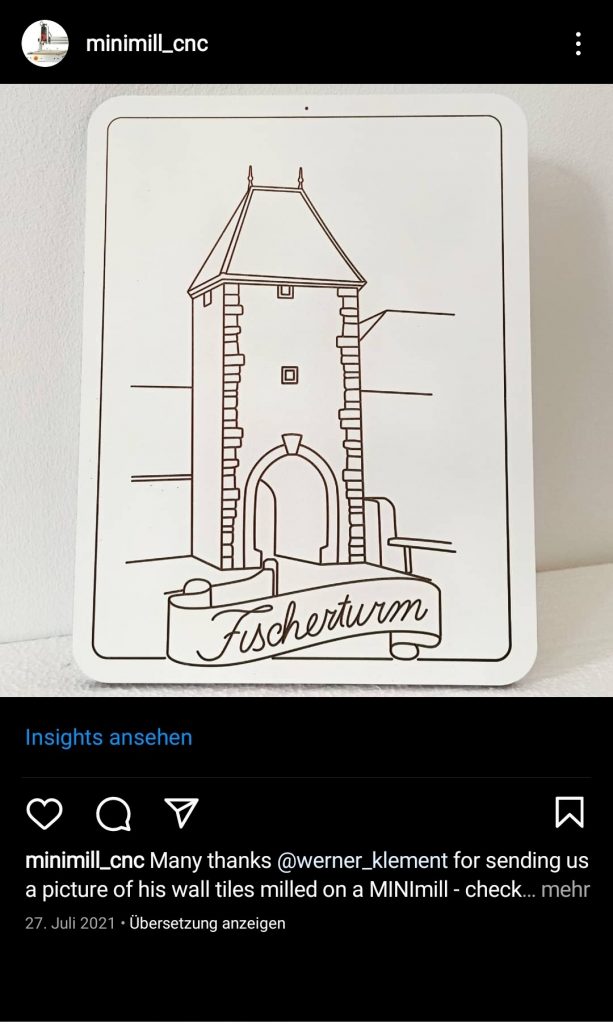

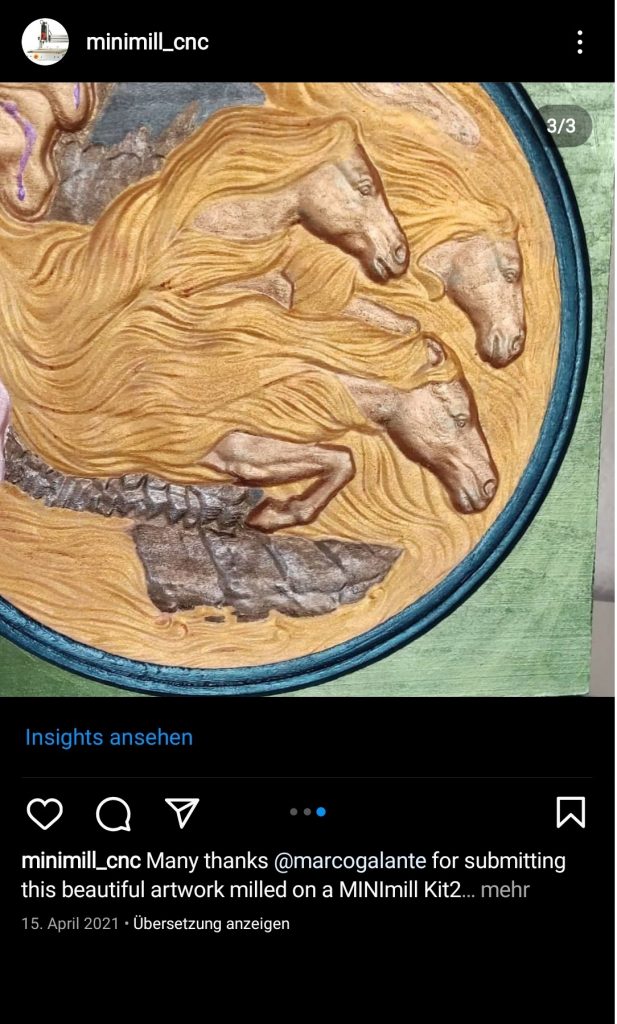

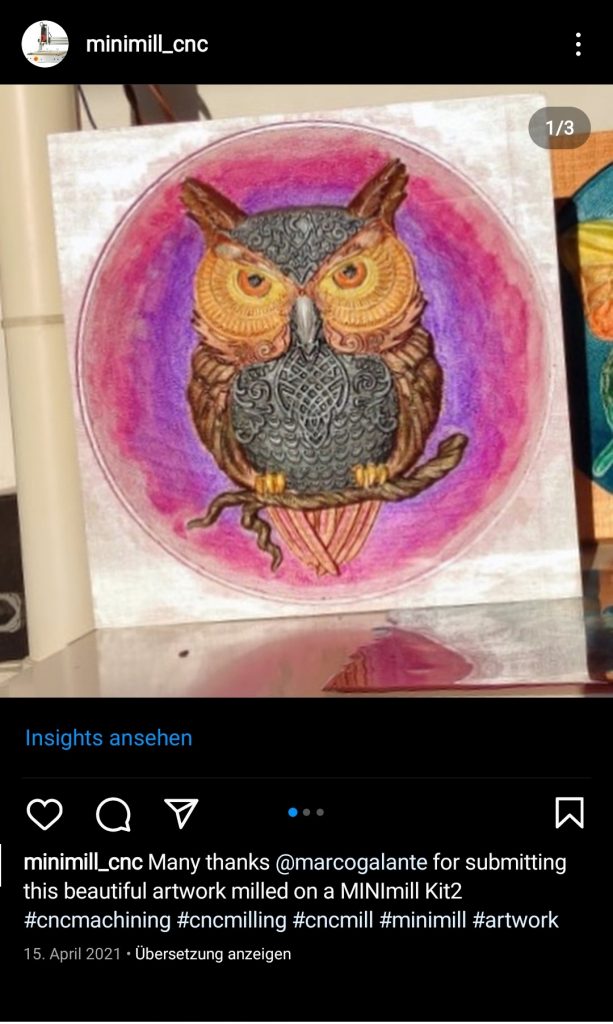

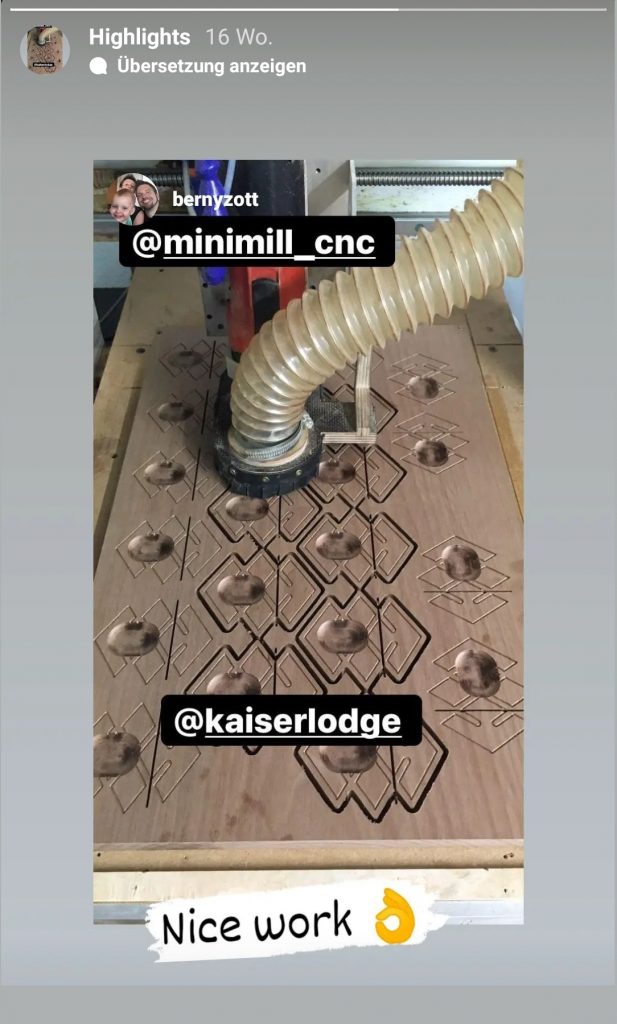

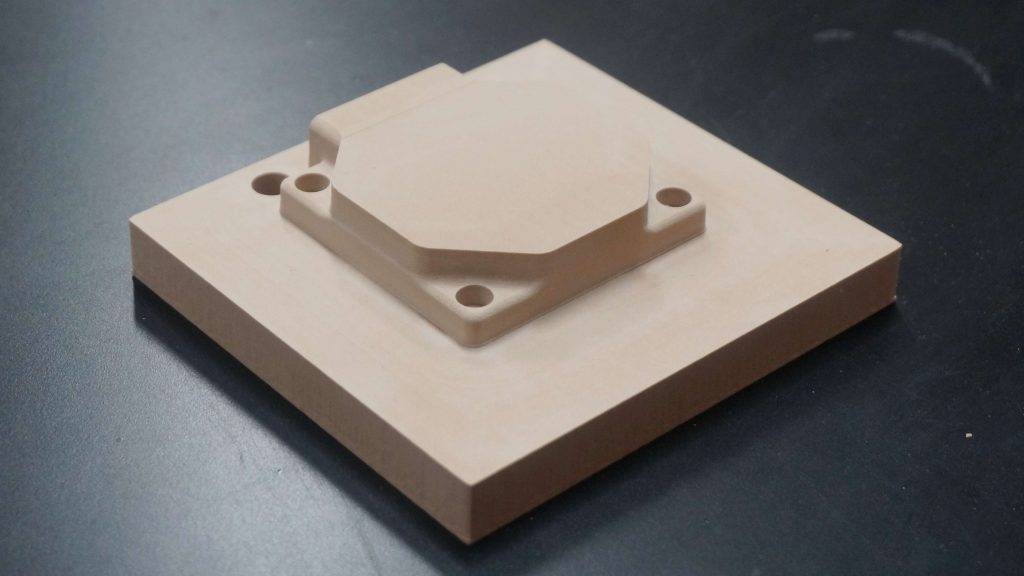

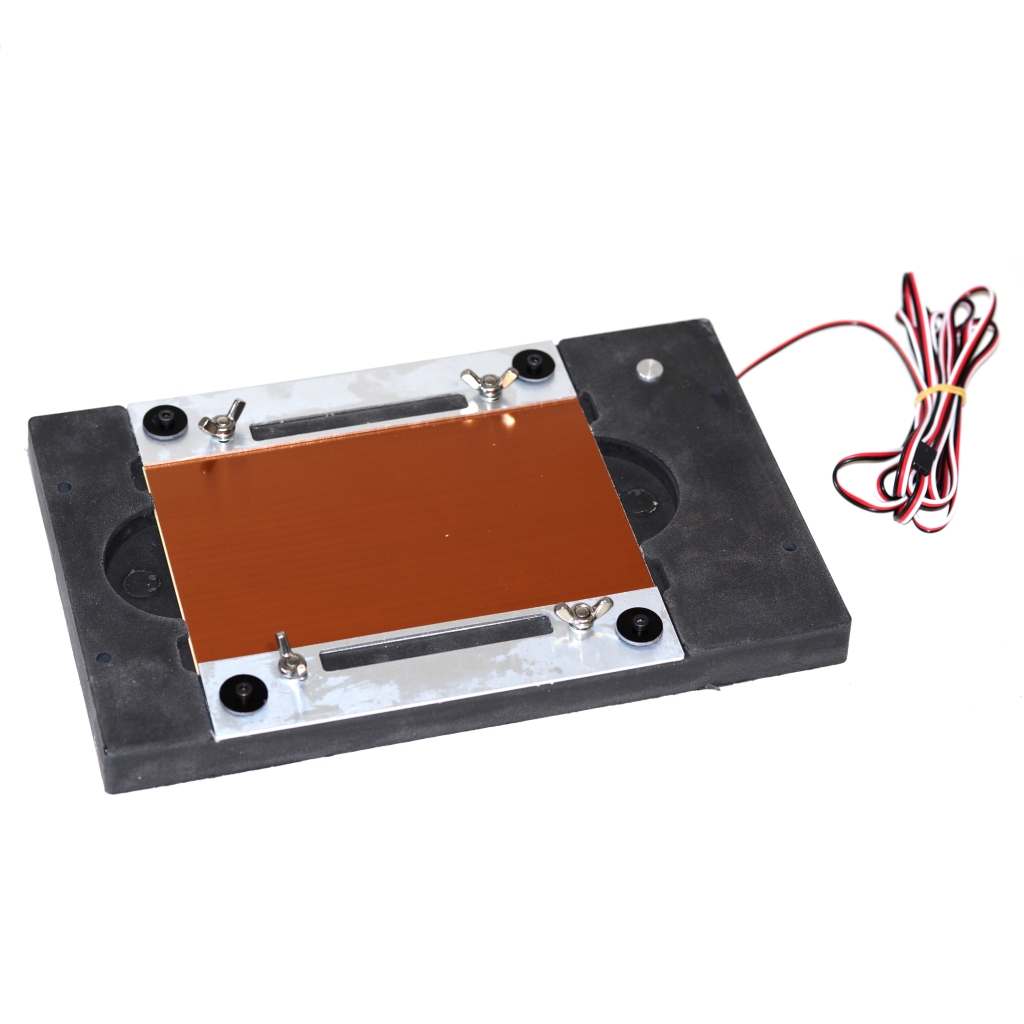

It was never easier to mill complex projects at home. The MINImill KIT2 manufactures 2 and 3 dimensional parts and pcb directly in your workshop.

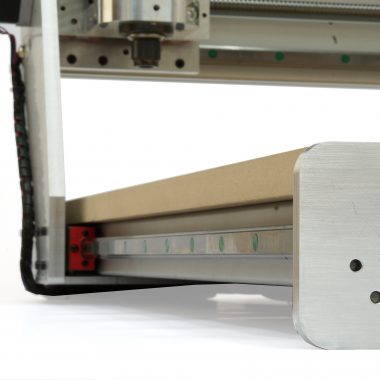

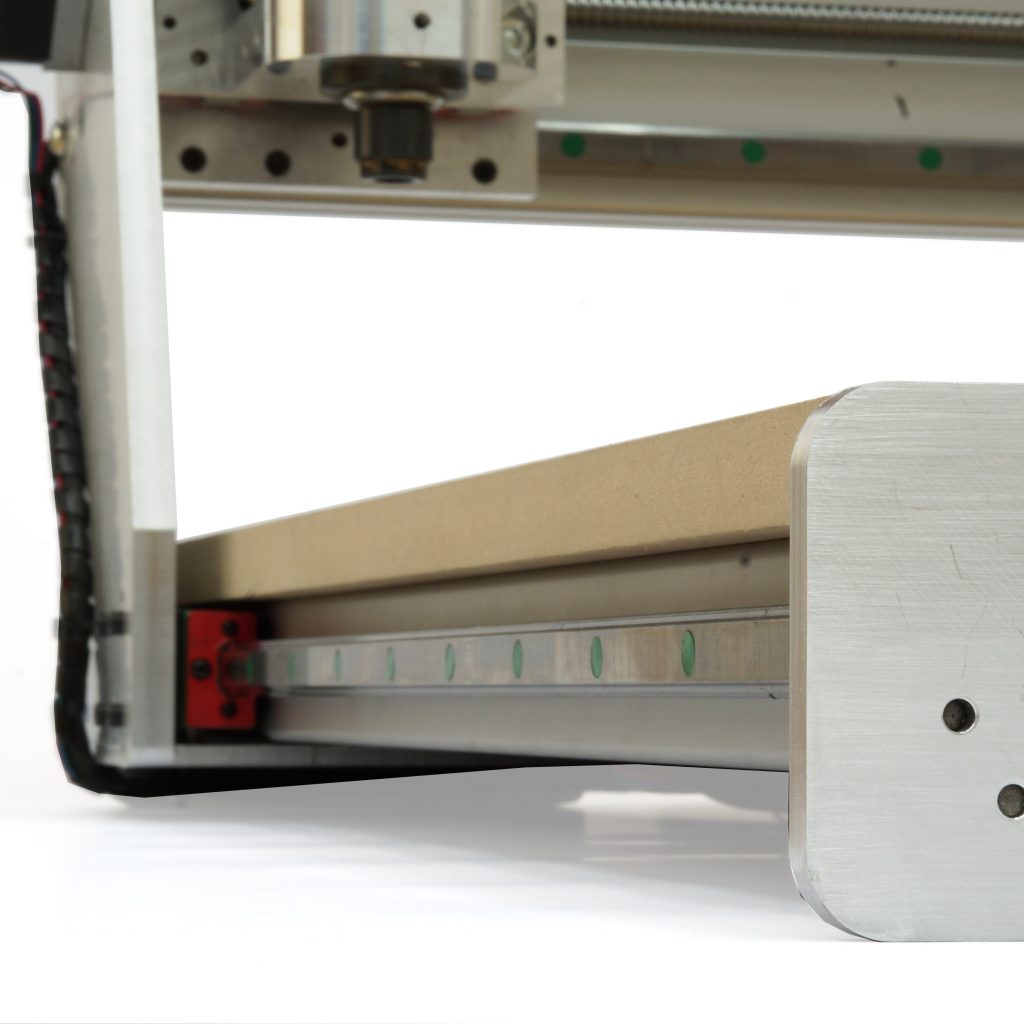

The MINImill KIT2 offers a milling area of 560 x 340mm and fits perfectly on your desk. You can manufacture parts from DXF, STL, GCODE and Gerber files directly with our MINImill software.

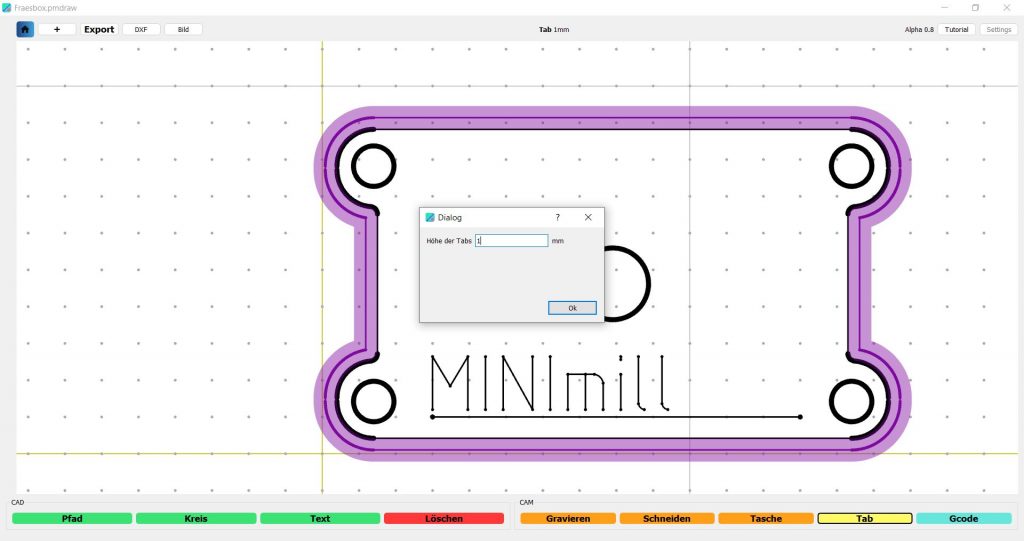

Our intuitive software helps you in making perfect parts directly in your workshop. Open and directly mill DXF, STL and Gerber files.

Deutsch

Deutsch